| Range of bending force | 250-4200Kn |

| Range of bending length | 3100-6100mm |

| Range ofthroat depth | 46-mm |

| Range of max. stroke | 150-400mm |

| Range of daylight | 340-600mm |

| Approximate workpiece max.weight | 200kg |

| Robotic max load-bearing capacity | 300kg |

| Stacking height of sheet metal | 1800mm |

| Stacking height | 1800mm |

| Air Pressure | 6-8Bar |

|turn over table

|Robot 7th axis

|Automatic gripper frame

|Automatic correction of sheet metal

|Gravity positioning platform

|3D visual system

The unidirectional mechanical deflection compensation mechanism adopts a unique specially processed wedge block. Each set of wedge blocks ls designed according to the deflection of the upper and lower beam. The cnc calculates the required compensation amount according to the load force when the workpiece ls bent, and automatically controls the relative movement of the wedge block to effectively compensate for deflection.The mechanical compensation system, as well as the hydraulic one, is certainly a great help for the operator during bending operation; it is reliable, precise and is not subject to any oil leakage.

Manual sliding front support arms EZ type (available for ghm and ghb series and ghl series)

Manual sliding front support arms sp type (Available for ght and ghl series)

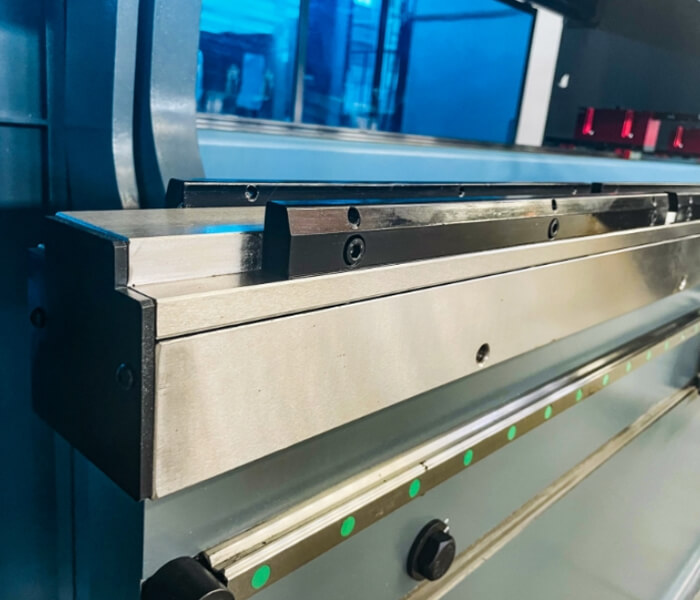

MANUAL BOTTOM TOOL CLAMPING MOD.GSB-M

Self-centering type. Available for 60-90 mm dies.

HYDRAULIC BOTTOM TOOL CLAMPING MOD. GSB-H

With ty-adjustment function. Allows to adjust in y direction every 200 mm which makes thus compensating the unavoidable tolerances mistake which accumulate during bending process. It possible to fully compensate for unavoidable -cumulative -processing tolerances in the press brake.

PNEUMATIC BOTTOM TOOL CLAMPING MOD GSB-P

Intermediate pneumatic and self aligning clamp.For quick release and tooling set up on machine.

MANUAL TOP TOOL CLAMPING MOD GST-M

Standard intermediate clamp with quick release lever for fast tool change. Suitable for vertical loading/unloading of tools. No need to slide the tools laterally sharing mode with moving.

HYDRAULIC TOP TOOL CLAMPING MOD. GST-H

Wila upper hydraulic clamping system allows to change tooling horizontally or vertically. Tools are self-seated and aligned automatically within seconds when pressing the button of a separated hydraulic power pack. All these features guarantees the operator a safe, fast and efficient bending process.

PNEUMATIC TOP TOOL CLAMPING MOD. GST-P

Intermediate pneumatic and self aligning clamps. For quick tooling set up and release on machine. No risk of any oil leakage.

The safety device (light guard) protects the operator from any accidental injury by stopping automatically the descent of the top beam when an obstacle (ex, operator’s fingers) enters the protection zone.